Goodyear welted shoes were introduced in 1869 in order to manufacture long-lasting pairs of shoes which could be easily resoled and recrafted to elongate the life of a single pair of shoes. High quality shoes are made from the best quality leather, with moderate use a pair of Good year welted pair shoes can be recrafted 3-4 times.

How are Goodyear welted shoes constructed?

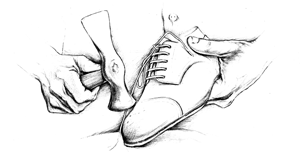

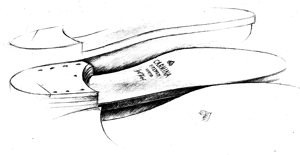

Essentially, a strip of leather is stitched to the shoe upper which leaves a welt upon which the sole is then stitched. Therefore, a space between the insole and the outsole is filled in with a cork mixture that will then be enclosed between both leather soles.

This particular way of manufacturing shoes will enable easy resoles as well as having a cork filling than is moulded to the wearer’s particular foot shape. We have added a small illustration to describe how our shoes are manufactured. A strip of leather (the welt) is stitched to the upper. A cork filling is added over the insole. The outsole is stitched to the welt.

How can I distinguish a Goodyear welted shoe from a Blake stitched pair of shoes?

Essentially, Blake stitched shoes are rarely resoled since it is much more labour intensive than resoling Goodyear welted shoes. By inserting your hand inside the shoe, you will feel the stitching of any Blake shoe on the insole. Goodyear welted shoes have around 150 manufacturing steps whereas Blake stitched shoes range around 50 steps.

What is a closed channel?

Goodyear welted shoes have a channel which is the small trench where the stitching connects the sole and welt. If the channel where not closed; we would be able to see the stitching on the sole. At Carmina, we cut into the sole to create a leather flap under which the sole is sewn to the welt. This flap is then pressed closed to conceal the stitching inside the sole itself. Closed channel shoes have a dressier look and require a higher level of craftsmanship.